Metals Recovery

Strategic Metals Recovery from Tailings and Mine Waste

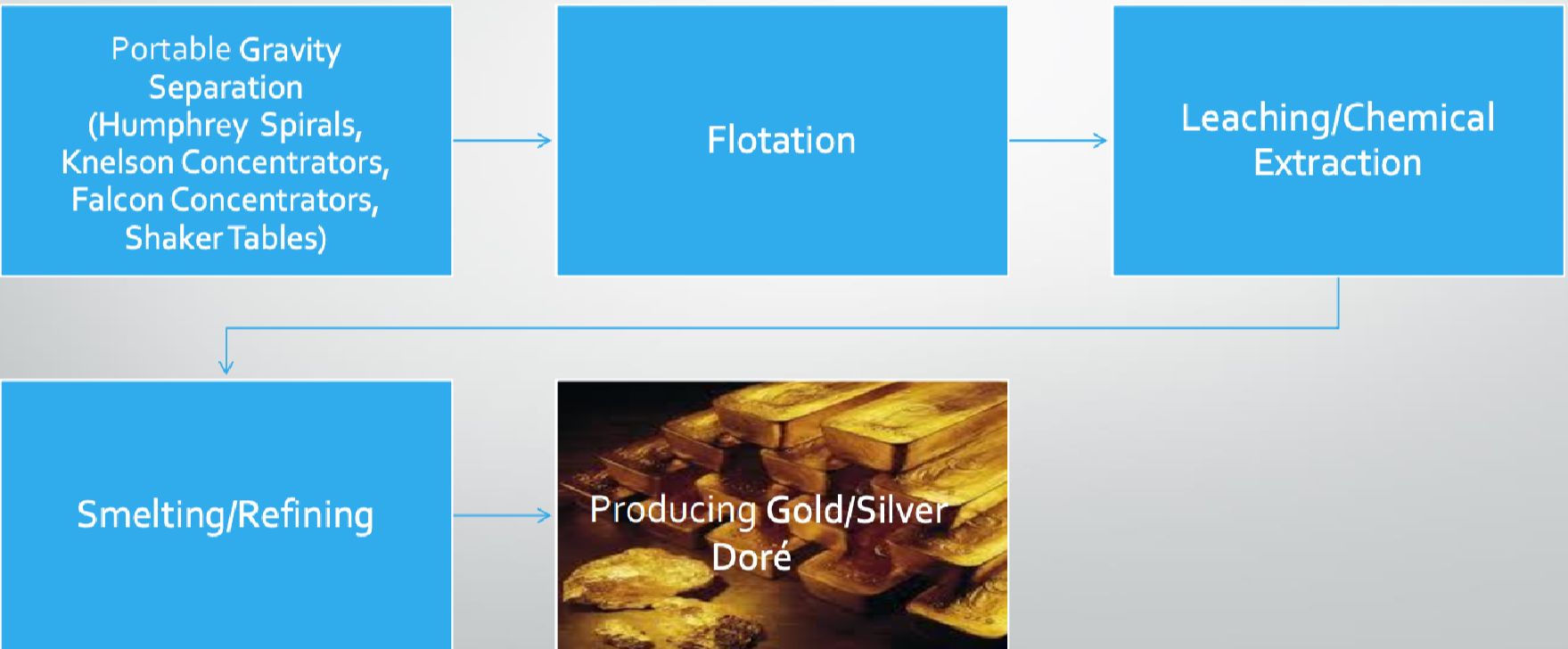

Process Diagram for Portable Tailings Processing

Tailings

Tailings from abandoned mines will be identified and analyzed for valuable metal sand materials.

Gravity Concentration

Free-gold bearing tailings will undergo spiral concentration to remove precious metals.

Froth Flotation

Remaining metal sulfides will then undergofroth flotation concentration.

Leaching and Chemical Extraction

Gold and other precious metals will then be leached by special developed properitary chemicals and extracted from the flotation concentrates.

Smelting and Refining

Gold concentrates and free gold from gravity separation methods will then be smelted and refined into gold doré bars and other metals.

Final Notes for your Recovery Operations

Why this is a success:

- We have done it before.

- There is an opportunity to recover metal from mine tails throughout the world from smaller mining districts more economically than normal mining methods.

- Large volumes of tailings from historical ores to abandoned mines create a life long industry.

- As an environmentally conscientious, our organization will be the solution, not the problem.

- We have and can set up your operation for portable operations

We May Partner With You

Using high technology, we can recover most metals in old mining districts—gold, silver, platinum, and other valuable metals—eliminating mining costs and hazardous metals from sludge, mine waters and old mine sites.

Special Problems?

Toxic Metals

We can help you reduce the volume of hazardous materials in soils and water that are to be left on-site to solve environmental problems. We use special engineered field classifiers, to handle fine and toxic metals which can then be smelted on site or sent to refiners to produce sellable metal products or doré bars. Acid mine water remediation - we clean waters from your industrial plant and your mine site.

We Recover Metals on Your Site With Portable Equipment

Why Not Resource Recovery and Recycling?

The developments our companies obtained in metal removals from contaminated soils polluting the environment in its operational history has allowed ETI Companies to process sludge, tailings, old factory sites, and old mining districts for precious and recoverable metals. We can save you operational and developments money by quickly converting waste into assets. Contact us for study.

Project Summary

ETI METALS as a US Veteran Owned Corporation is Established as an International Mineral/EnergyCompany operating as an Environmental Resource Recovery Company specifically for the purpose of the following:

- We Identify and acquire old, abandoned, non-operating mill or unused mine sites in the precious metals area (i.e. gold, platinum, and silver).

- We Utilize these old mill sites and historical mine tailings which contain known deposits of gold, platinum, silver, copper, lead, zinc, as well as rare earths and other strategic metals, and recover the metals to leave a clean site for further develpment.

- We Mine historical tailings and mine waste during the exploration for valuable metals and investigate the surrounding area for additional mineral resources. Simultaneously, open operations where known metal deposits, the company or country controls, or exists at abandoned historic mills, artesian mines to leave a clean site for future use and protect the environment.